Supply Chain Optimization – Localized Decision-Making

Local supply chain decision-makers have a clear edge, with an impressive 83% likelihood of making informed and effective decisions

This can be largely attributed to their immediate, hands-on involvement in operations, which lends them unique insights—a clear demonstration of the value of localized decision-making in supply chain optimization. Furthermore, evidence shows that decisions grounded in a localized or cross-functional approach prove practically successful in 57% of instances, underscoring their effectiveness.

But how this can be achieved?

The answer lies in adopting a localized and cross-functional approach to decision-making.

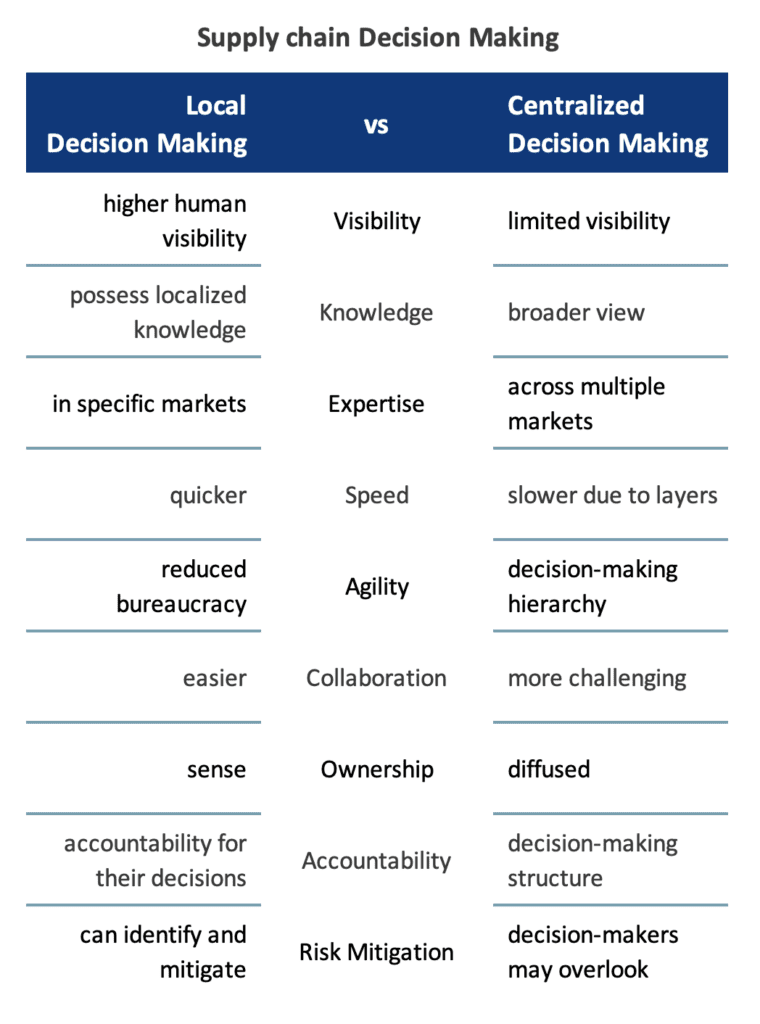

Here’s what a local decision-maker brings to the table:

- Deep Knowledge of Relevant Variables: They have a keen understanding of the variables that should be factored into their decision models.

- Comprehensive Variable Inclusion: They ensure all pertinent variables are accounted for in their decision models.

- Assurance of Data Accuracy: They validate the data representing these variables, ensuring it is precise and reliable.

What is the implication of integrating digital technology with localized decision-making?

Presently, the digital analytics tools at our disposal tend to favor global decisions over local ones.

It’s crucial to harness the unique perspective of local decision-makers. Armed with specialized knowledge about their region, suppliers, and customers, local decision-makers’ insights can be instrumental in enhancing operations, spotting opportunities, and effectively managing risks.

We should focus on these three key areas:

- Digital Transformation of Local Decision Models: Move towards the digitization of local cross-functional decision models to streamline processes.

- Global Technology Infrastructure Development: Refine the global technological framework to expedite localized and cross-functional decision-making.

- Customer Empowerment: Enable customers to take the reins, equipping them with the tools they need to become self-reliant in their transactions and interactions.

How did we do it?

Case Study: Optimizing Supply Chain Decision-Making through Localization

Introduction:

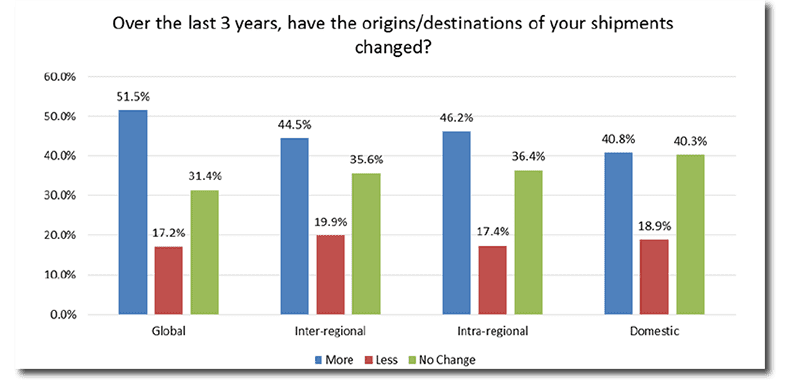

In today’s globalized world , characterized by intricate business landscapes, optimizing decision-making in supply chain management is the linchpin of seamless operations and the preservation of a competitive edge. This case study takes a deep dive into the transformative influence of localized decision-making within the scope of supply chain management. It explores how local supply chain decision-makers, with their heightened human visibility and proximity to operations, are more likely to make good decisions, resulting in improved overall performance.

Background:

Our client is a multinational manufacturing corporation which operates in multiple countries and has a complex global supply chain network. As a producer of consumer electronics, they need to ensure tight-knit coordination among a range of suppliers, distributors, and retail partners to meet the demands of their customers effectively and efficiently.

Implementing Localized Decision-Making:

Our client’s transformation strategy, focused on ‘Supply Chain Optimization – Localized Decision-Making’, revolved around decentralizing the decision-making process. This innovative approach empowered local managers and employees, leveraging their intimate knowledge of regional nuances and specific expertise. To foster a comprehensive perspective on decision-making, cross-functional teams were established, composed of members from procurement, production, logistics, and sales departments.

Embracing the digital age, our client recognized the value of incorporating technology to streamline their supply chain operations. Key digital technologies included:

- Real-Time Data Analytics: The company implemented robust data analytics systems that collected and analyzed real-time data from diverse sources, including sales, production, inventory, and logistics. This gave local decision-makers access to timely, accurate information, and the ability to make data-driven decisions based on the real-time status of the supply chain.

- Supply Chain Visibility Platforms: The deployment of these platforms allowed decision-makers to track and monitor the flow of goods throughout the supply chain. These platforms integrated data from various stakeholders—including suppliers, manufacturers, logistics providers, and retailers—providing a comprehensive view of the supply chain and facilitating cross-functional collaboration.

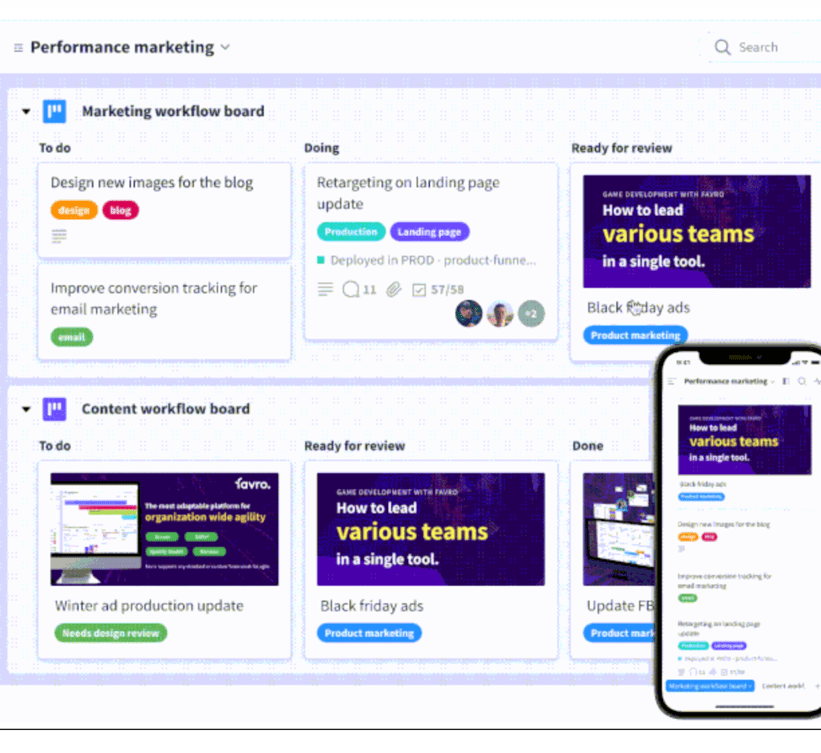

- Collaborative Planning Tools: The company adopted collaborative planning tools to foster real-time communication and collaboration among local teams. These tools promoted real-time communication, document sharing, and collaborative decision-making, resulting in improved coordination, faster resolution of issues, and better alignment of supply chain activities.

By empowering local supply chain decision-makers, capitalizing on their unique human visibility, and promoting cross-functional collaboration, we observed a significant uplift in decision-making effectiveness and overall supply chain performance. This case study underscores the power of localized decision-making as a strategy to drive operational excellence and secure a competitive edge in a fast-paced, complex business environment.