Supply Chain Healthcare inventory

Chief Supply Chain Officers are perpetually on the quest for strategies to elevate their departments, with time and cost efficiency at the forefront. How to master organizational execution to achieve this KRA?

How to master Organizational execution?

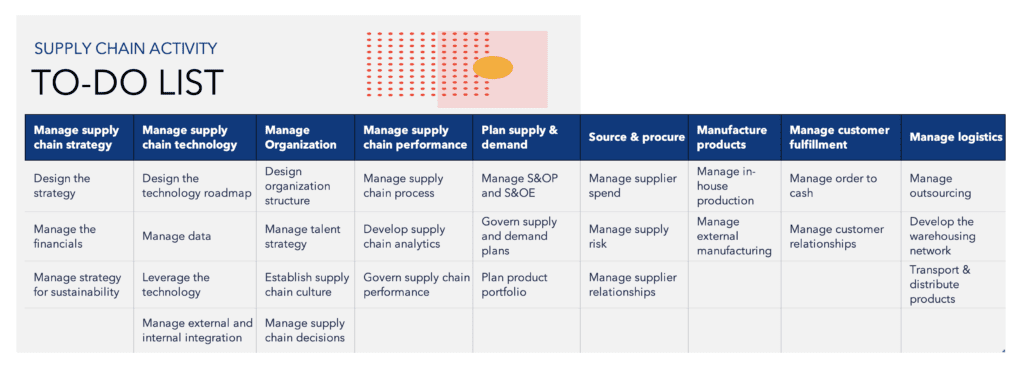

There are 27 key supply chain activities. Efficiently administering and mastering these activities can significantly enhance organizational execution to manage Supply chain functions like Planning, Sourcing & Procurement, Inbound & Outbound Logistics, Manufacturing, and Warehouse & Inventory Management, as well as Distribution.

How did we do it?

Revolutionizing Supply Chain Inventory Management: A Case Study in the Healthcare Industry

Abstract:

This case study showcases the successful implementation of an advanced inventory management system for a healthcare customer to streamline their supply chain. Facing significant losses due to inefficient handling and lack of proper inventory maintenance, the hospital collaborated with our organization to overhaul its inventory management processes. Through an accuracy rate of 87%, shrinkage amounting to a staggering 1.5 million USD was eradicated, paving the path for enhanced cost savings and superior operational efficiency.

Challenges:

Inventory management plays a vital role in the healthcare industry, where the misplacement or loss of key items can have severe consequences. Recognizing the need for robust inventory control, a healthcare provider engaged our organization’s expertise to address their persistent inventory management challenges. This case study portrays the successful implementation of an accurate inventory management system, resulting in substantial cost savings and improved operational efficiency.

Background:

The healthcare provider faced significant losses in their inventory, primarily due to the mismanagement and inadequate record-keeping of small, bulk-packaged items. The absence of precise tracking and maintenance processes resulted in inventory shrinkage and substantial financial losses for the hospital. Consequently, they approached our organization to implement an efficient inventory management solution.

Objectives:

The primary objectives of the project were as follows:

- Enhance inventory accuracy and visibility.

- Eliminate shrinkage and losses caused by inefficient inventory handling.

- Improve cost savings and operational efficiency.

- Streamline inventory management processes.

Methodology:

A systematic approach was adopted to address the healthcare customer’s inventory management challenges.

- Assessment and Gap Analysis: Performed a comprehensive understanding of the client’s current inventory management processes, identification of lacunae, and strategizing potential solutions.

- System Design and Implementation: Designed and deployed a cutting-edge inventory management system, customized for the unique needs of the healthcare sector, including barcode scanning, automated stock reconciliation, and real-time inventory tracking.

- Training and Change Management: Intensive training sessions were held to acquaint hospital staff with the new system, underlining its advantages and addressing any concerns or resistance to change.

- Monitoring and Support: Continuous technical support and system performance monitoring were ensured for seamless integration within the hospital’s operations.

Solution Context:

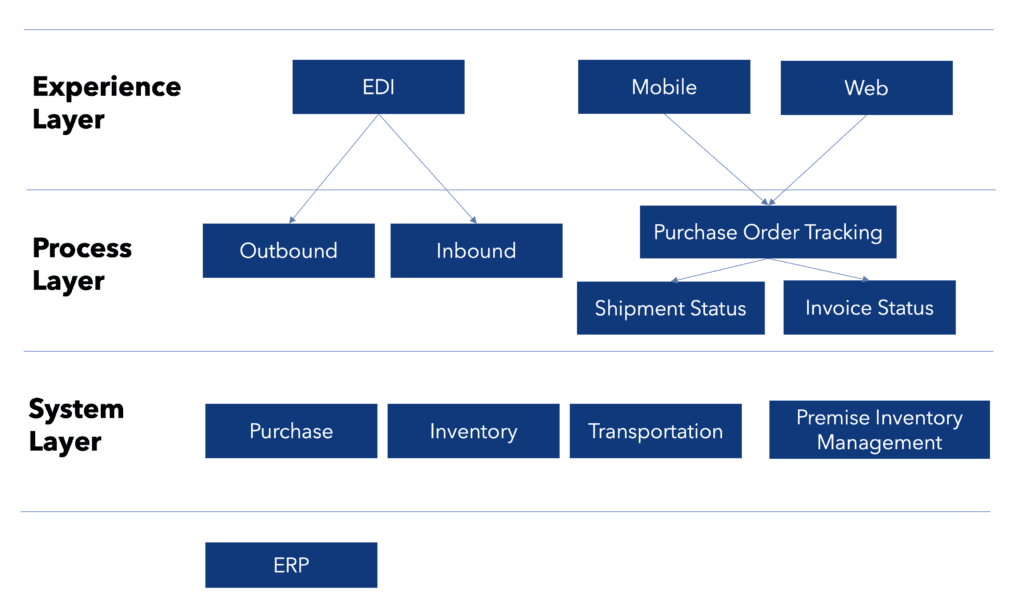

The solution can be visualized in the diagram below.

The experience layer emphasizes user-centric design and interface, the process layer focuses on optimizing operational workflows, and the system layer deals with the underlying infrastructure and technical aspects of the overall system. These layers work together to provide a seamless, efficient, and reliable experience for users and ensure the successful functioning of the system.

Results and Analysis:

Following the implementation of the advanced inventory management system, the healthcare customer achieved remarkable results:

- Increased Inventory Accuracy: An impressive accuracy rate of 87% dramatically cut down discrepancies, enhancing visibility into the hospital’s inventory. This facilitated more precise item tracking, mitigating the risk of misplacements and stockouts.

- Eliminated Shrinkage and Losses: With precise tracking and real-time inventory updates, the hospital successfully neutralized shrinkage and losses associated with the small packaged items. The financial repercussion translated into cost savings estimated at 1.5 million USD annually.

- Enhanced Operational Efficiency: The streamlined inventory management processes resulted in improved operational efficiency. Staff members could swiftly locate items, cutting down the time expended in searching for inventory and allowing for superior resource allocation.

- Improved Patient Care: The implementation of an accurate inventory management system ensured that the hospital always had the necessary supplies at hand. This resulted in superior patient care, minimizing any delays or disruptions caused by inventory shortages.

By deploying an advanced inventory management system with an accuracy rate of 87%, the healthcare provider successfully surmounted their inventory management challenges. The hospital witnessed significant cost savings and operational enhancements, eradicating shrinkage worth up to 1.5 million USD annually. This case study underscores the crucial role of efficient inventory management in the healthcare sector, empowering organizations to optimize resources, enhance patient care, and realize significant cost savings.